Dashboards are easy. Action is hard. This post explores how AI in manufacturing must go beyond monitoring and surface insights that lead to real, executable decisions.

Overview#

We’ve all seen the promise: collect data, train models, visualize results. The modern factory is drowning in dashboards. Every vendor promises insights and visibility. And yet, when something goes wrong, engineers still spend days or weeks reconstructing events, comparing materials, and searching for root causes.

The problem isn’t a lack of data. The problem is the gap between knowing and doing.

Manufacturing is fundamentally about action. Pressing buttons, moving materials, adjusting parameters, correcting defects.

Insight without action is entertainment.

A factory, even of the future is not a passive experience, it’s a full on contact sport. Where hard decisions have to made, where we train, plan and execute. But where executing is king.

The true value of any intelligent system in manufacturing is not what it sees, but what it enables you to do about it.

This is the missing piece in most AI deployments: The Closed Loop.

The Incomplete Loop#

Most AI implementations in manufacturing stop at visibility. The typical flow, for event the most advanced applications, goes something like this:

- Collect data from sensors, machines, and processes

- Store that data in a historian or data lake

- Visualize it in dashboards

- Analyze patterns using statistical or ML methods

- (Optional) Generate alerts when thresholds are breached

This is valuable. But it’s incomplete.

The operator sees an alert. Now what? They must:

- Interpret the alert

- Gather additional context

- Investigate root cause

- Decide on corrective action

- Execute that action somewhere else (often manually)

- Document what was done

Each of these steps introduces delay, inconsistency, and the potential for human error. The system told them what is wrong, but not why, and certainly didn’t help them act.

I am not even talking about the problems faced when we have multiple applications owners of different subsystems inside the factory and being monitored by totally different people.

The Complete Loop#

The intelligent factory doesn’t stop at alerts. It closes the loop:

- Collect vast amounts of structured data

- Contextualize that data with process, material, and equipment relationships

- Enable exploration through natural language and AI-assisted queries

- Surface insights that explain not just what happened, but why

- Execute actions directly in the control system

This is the difference between a dashboard and a control system. One shows you a problem. The other helps you solve it.

Why Context Is Everything#

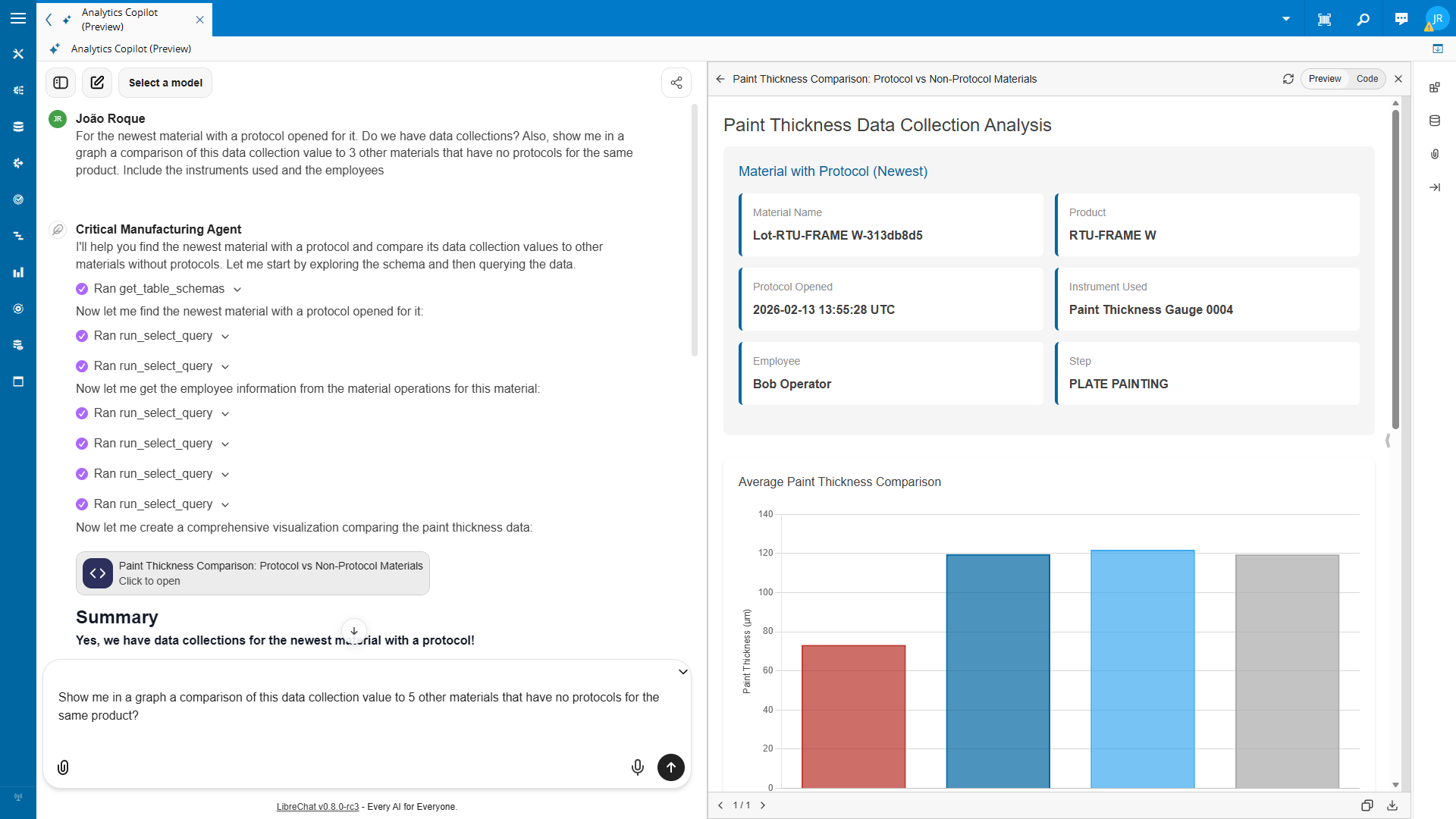

Raw data is meaningless without context. A temperature reading of 73.22 tells you nothing. But 73.22 μm paint thickness on Lot-RTU-FRAME W, applied at PLATE PAINTING by Bob Operator using Gauge 0004 tells you a story.

This is where the MES becomes essential. An MES doesn’t just collect data. It already knows:

- Which material is being processed

- At which step and resource

- By which operator

- With which equipment and parameters

- Against which specification

When a problem occurs, the MES can correlate across all these dimensions instantly. The data isn’t a spreadsheet waiting to be analyzed. It’s a knowledge graph waiting to be queried.

Conversational Exploration#

Here is where modern AI changes the game.

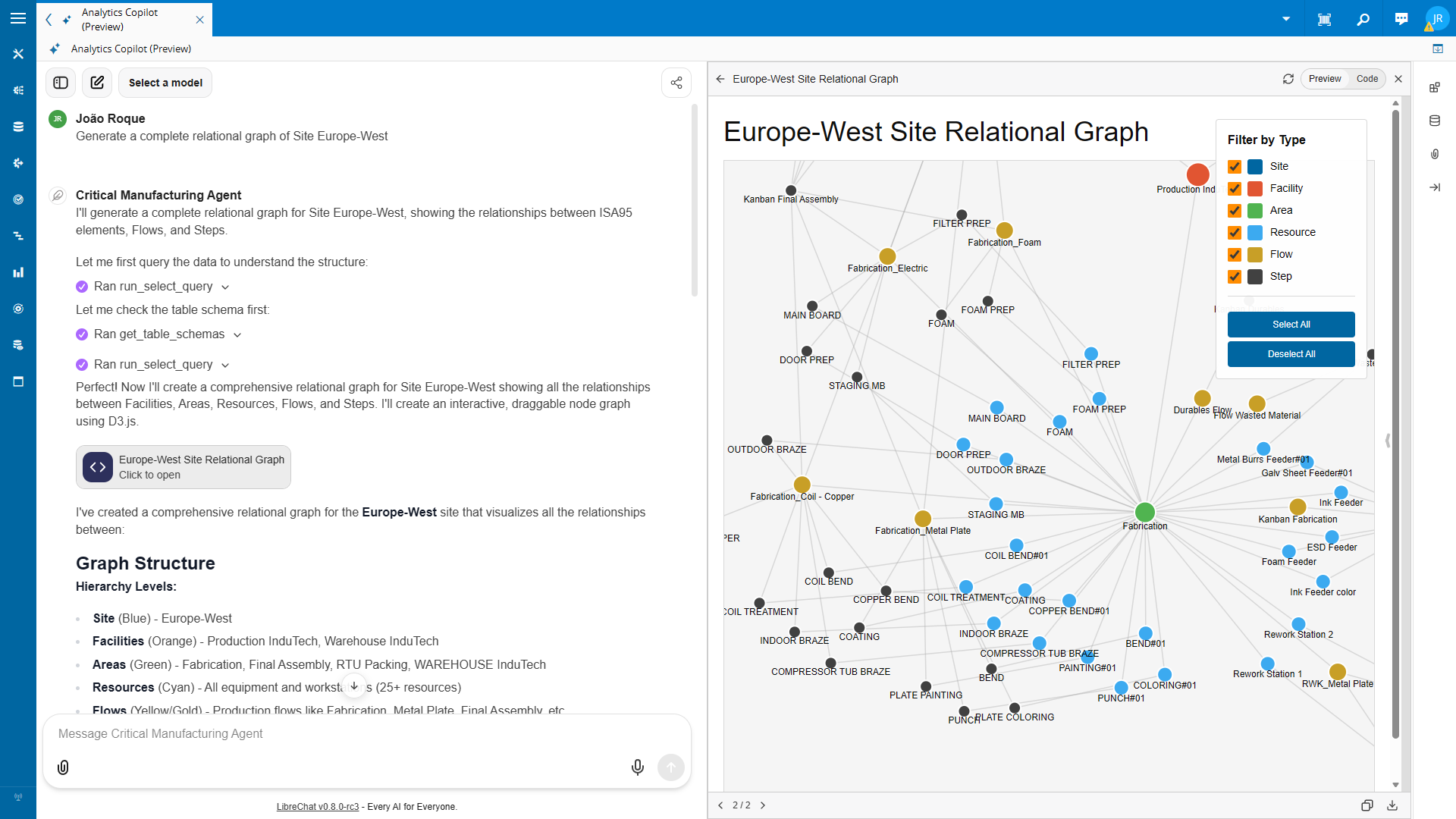

“Generate a complete relational graph of Site Europe-West, with draggable nodes”

Generated by AI:

Without any knowledge of the system, you have an instant graph visualization of your system. You are able to explore critical chokepoints, critical connections in a complete bird’s eye view of your shopfloor.

Instead of building predefined reports for every possible question, we can now ask questions in natural language and let the system explore the data on our behalf.

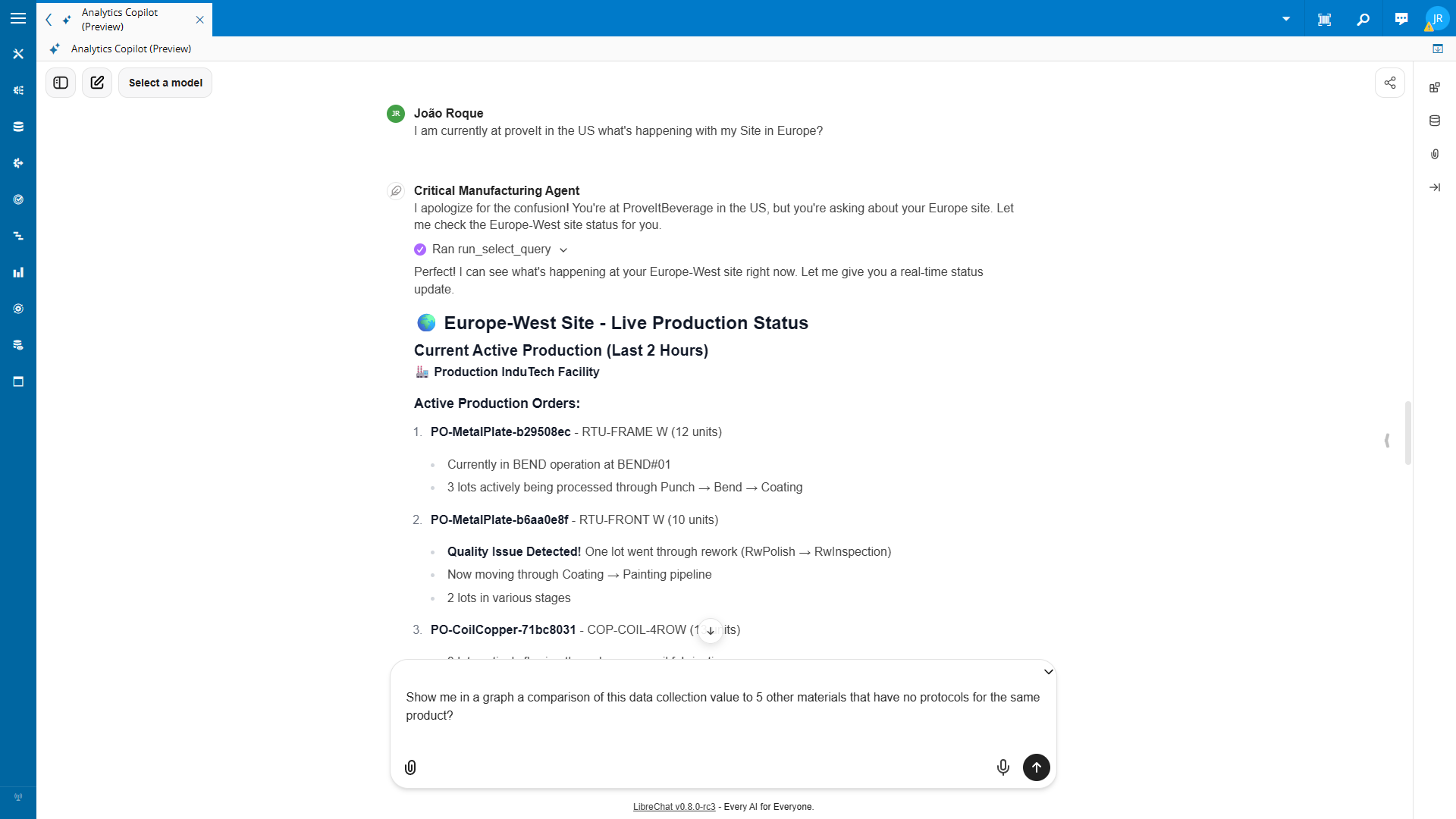

With just a simple question we can understand what is happening in remote geographies.

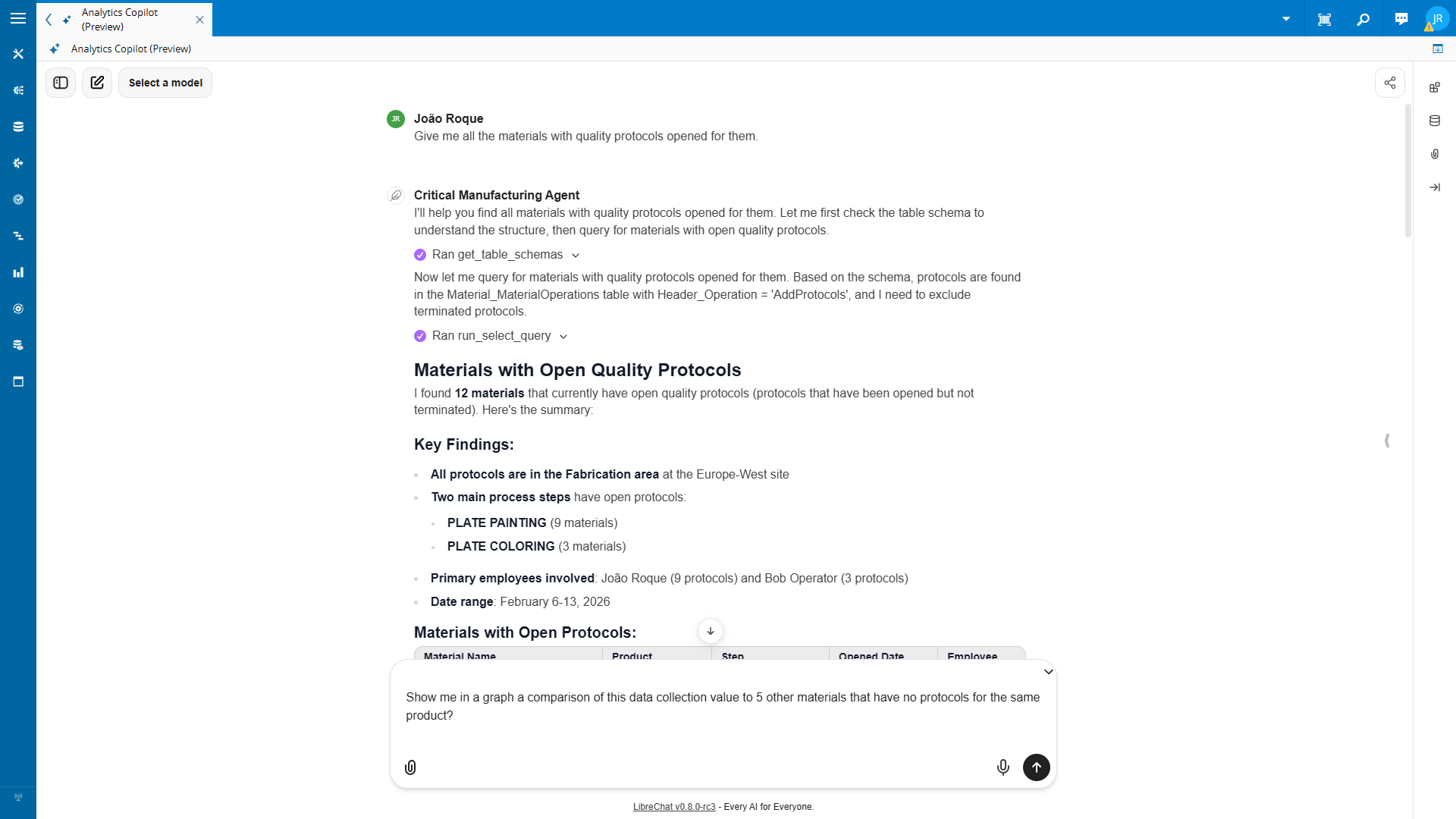

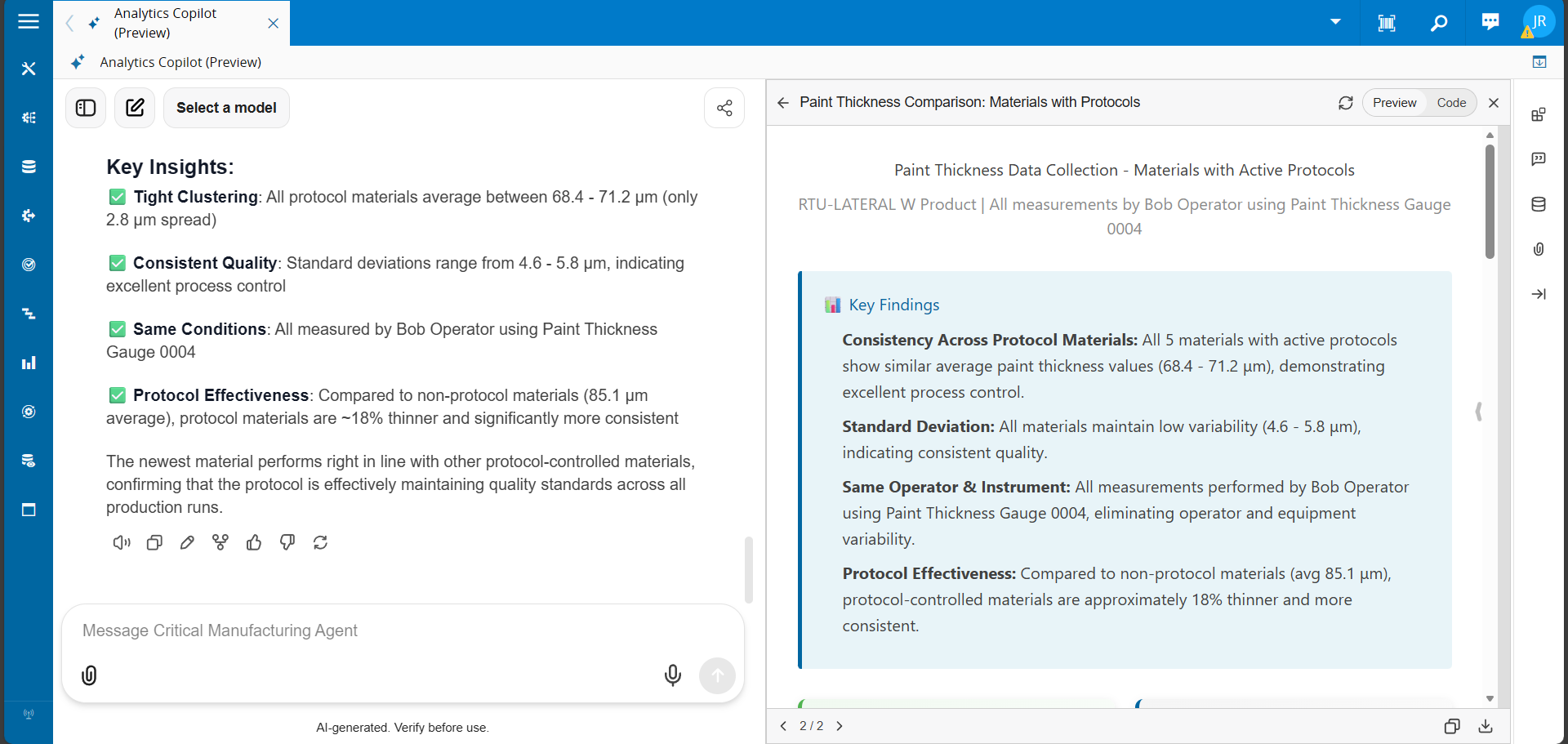

Consider a real scenario. Quality protocols (or non-conformances) have been opened for several materials. A quality engineer wants to understand what’s happening. Instead of trying to correlate information between different systems and reports. They just ask:

“Give me all the materials with quality protocols opened for them.”

The system responds with a structured answer: 12 materials, primarily at the PLATE PAINTING step, associated with specific employees and dates.

Now they dig deeper:

“For the newest material with a protocol opened for it, do we have data collections? Show me a comparison to 3 materials without protocols for the same product. Include the instruments used and the employees.”

Generated by AI:

The system correlates telemetry, quality results, and execution context. It returns:

| Material | Paint Thickness | Instrument | Employee |

|---|---|---|---|

| Protocol Material | 73.22 μm | Gauge 0004 | Bob Operator |

| Good Material 1 | 119.58 μm | Gauge 0001 | John Operator |

| Good Material 2 | 121.87 μm | Gauge 0001 | Tim Operator |

| Good Material 3 | 119.43 μm | Gauge 0001 | John Operator |

He formulates a hypothesis. Well, Bob is the new guy and Gauge 0004 is one of the old gauges. Can this be why we’re having issues?

“For the other recent quality protocols, who was the operator and what gauge did they use?”

Generated by AI:

The pattern is obvious: the material with the protocol has 40% thinner paint, a different gauge was used, and a specific employee is associated with the anomaly.

This is not speculation. This is evidence grounded in context. The AI didn’t replace the engineer. It made them dramatically faster at discovering root cause.

He’s able to leverage his experience and his intuition and knowledge of the shopfloor and do an instant exploratory analysis, in a couple of minutes.

The Final Mile: Action#

But here’s where most systems fail. The engineer has the insight. Now they need to act.

In a traditional setup, they would:

- Open a separate system (maybe a paper form, maybe an email)

- Write up the finding

- Create a corrective action request

- Assign it to someone

- Hope it gets followed up

In a closed-loop system, the engineer can:

- Navigate directly to the quality protocol in the MES

- Create a corrective action task in the same interface

- Assign responsibility

- Track resolution

The action is recorded, traceable, and connected to the original evidence. The loop is closed.

This is not a minor improvement. This is the difference between analysis paralysis and disciplined action.

Why MES Is the Right Place#

An MES sits at the intersection of data, process, and action. It is uniquely positioned to close this loop because:

It owns the execution layer. The MES controls what happens on the shopfloor. It can trigger workflows, quarantine materials, create tasks, and notify stakeholders.

It provides structured context. Unlike a generic data lake, the MES already knows the relationships between materials, processes, equipment, and specifications.

It enforces discipline. Actions in the MES are not suggestions. They are tracked, auditable, and part of the compliance record.

It integrates with AI natively. Modern MES platforms can ingest canonical events, run ML models, and expose natural language interfaces without leaving the system.

When AI lives inside the MES, insights become actions. The factory doesn’t just know. It does.

Beyond the Dashboard#

The manufacturing industry has been oversold on visibility. We have more charts, more graphs, and more alerts than ever before. And yet, problems still take too long to solve.

The next frontier is not more data. It’s better action.

AI in manufacturing must:

- Collect data automatically and continuously

- Contextualize it with process and product knowledge

- Enable exploration through natural language

- Surface insights that explain causality

- Close the loop with executable actions

This is the intelligent factory. Not one that watches. One that acts.

Final Thoughts#

The true value of an MES is not just insight. It is disciplined action.

Seeing problems is easy. Being able to act correctly and consistently is the hard part. That is where the MES proves its value. It doesn’t just tell you what happened. It helps you respond, consistently, traceably, and immediately.

The future of AI in manufacturing isn’t better dashboards. It’s better decisions, faster execution, and closed loops.

The question isn’t whether your factory has enough data. It’s whether your data leads to action.